Welcome to the Lab: A Q+A with Steve Gaurin

Lab manager Gaurin keeps the lights on and the auto-analyzers running in the Woodwell Lab

Steve Gaurin gives visitors a tour of Woodwell’s lab space.

photo by Julianne Waite

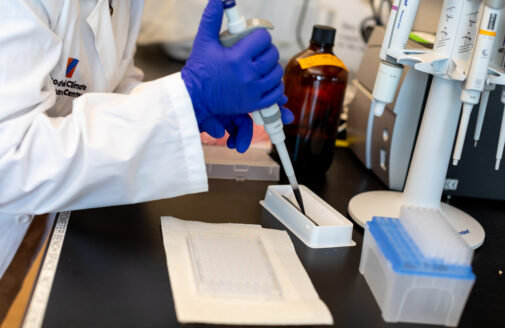

Lab Operations and Field Safety Manager, Steve Gaurin oversees the operations of Woodwell Climate’s four lab spaces, running them efficiently and effectively so researchers can generate the data they need for their studies. His day to day job involves regular maintenance on the complex machinery, troubleshooting glitches, maintaining safety procedures, and ensuring the Center’s scientists have the required materials to analyze samples and collect data. Here, Gaurin discusses what it actually takes to keep the lab running in top form.

SR: So, Steve, tell me about the Woodwell Lab.

SG: The lab is an essential piece of any research that takes place at the Center. It’s incredibly important to ensure our data is accurate and generated by reliable instruments; that’s a big part of my job.

We have four lab spaces at the Center— the main lab on the 3rd floor, our basement lab which is mostly used for soil sample prep, the gas chromatograph room, and somewhat disused at present, the shed lab.

SR: What do you wish more people knew about lab operations?

SG: The amount of effort and time and energy it takes to keep all these instruments running. They are incredible pieces of technology, but they’re also quite complicated, and there’s a number of different ways that they can go wrong. And they do. So when I say in a staff meeting, “all the instruments are working well” that’s a real statement, because it’s not always the case.

SR: And when problems with the instruments do pop up?

SG: It takes a lot of problem solving, almost like detective work to get to the bottom of it.

SR: Do you enjoy detective work?

SG: I enjoy it when we figure it out. Then it’s like one of the best feelings of my day. It feels like a triumph. The research assistants are happy, the PIs are happy. I’m happy. Everything’s good.

SR: But I take it we don’t always figure it out?

SG: Yeah, as I mentioned, these instruments are incredibly complex, and there are a number of ways that they can fail. For example, one of the soil analyzers, it has so many different O rings at all its connection points and if any one of those O rings is a little bit askew, it’s going to fail a leak test. Or the problem could be the flange seal at the top of the combustion tube. Or any number of things. Even though it seems like these things are simple input-output devices, the technology, the electronics, the chemistry, the physics, everything that went into those is nothing short of remarkable.

SR: Sounds like it’s a tall order to keep all these complicated instruments running.

SG: It’s not just me. Any time that I’m trying to solve a problem with anything in the lab, I’m working with the research assistants. And in many cases, it’s those discussions and those interactions with them that really get to the heart of the problem—and to the solution. In our last case with the nutrient analyzer, it was a lot of sleuthing from Andie Norton that really identified the problem. It’s essential to have the input and ideas of the people who really run the instruments most often.

SR: The lab, I imagine, also requires a lot of material resources to keep running.

SG: Yes. Most of the instruments run in the range of, say, 50 to 80 thousand dollars new. As we purchase new instrumentation, we also purchase service contracts for preventative maintenance visits and access to a technician, which is also incredibly valuable for troubleshooting. The other thing these instruments also need is consumables. You constantly need to be ordering those as supplies get depleted—chemicals, gas cylinders and the like. It’s not cheap but it’s crucial.

SR: What are your goals for the future of the lab?

SG: I think that the main goals for the lab are to continue to maintain and keep striving for that level of reliability, excellence, and cutting edge research that we’ve been conducting since before I got here.